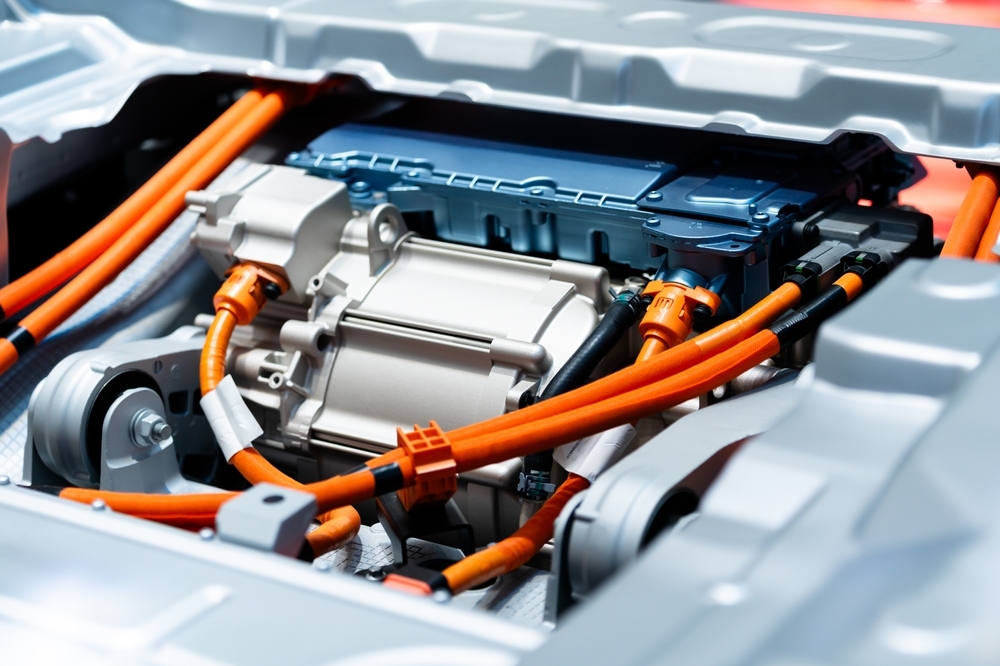

Smart GaN HEMT + IGBT = EV success?

Cambridge GaN Devices is targeting the powertrain of electric vehicles with the combination of IGBTs and its proprietary integrated circuit enhancement GaN technology.

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

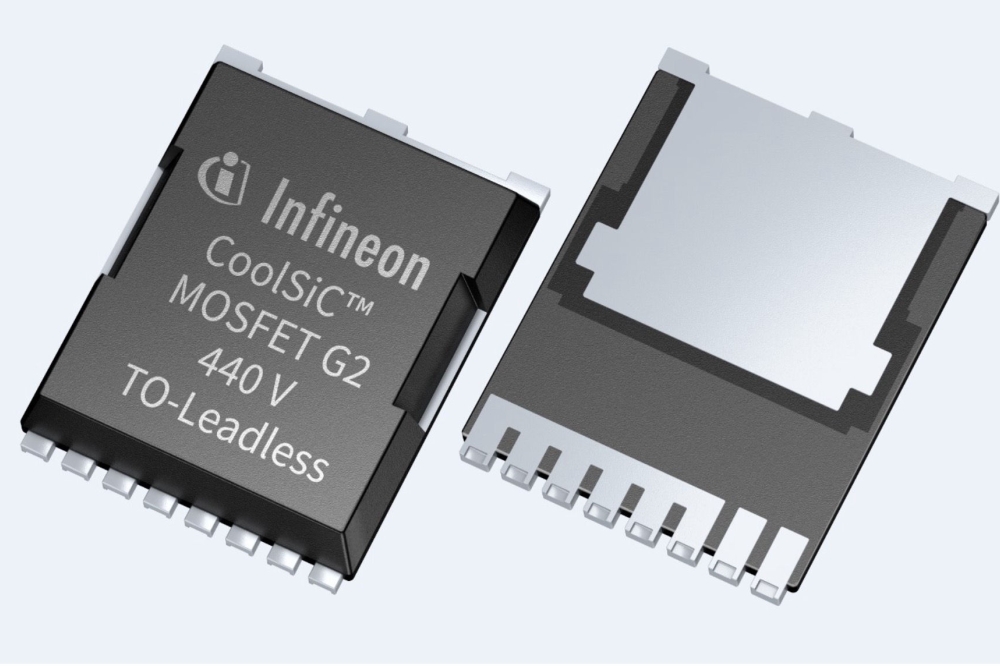

Today’s designers of power trains for electric vehicles face a difficult choice. Should they view cost as paramount and select silicon IGBTs; or should efficiency be the priority, and they deploy SiC MOSFETs? Whichever they choose, a significant compromise will be made.

But now there’s the promise of a third way, pioneered by a handful of producers of GaN – they are claiming that they could offer products with a price close to that of silicon solutions, while delivering an efficiency similar to that of SiC, by pairing a GaN HEMT with a silicon transistor.

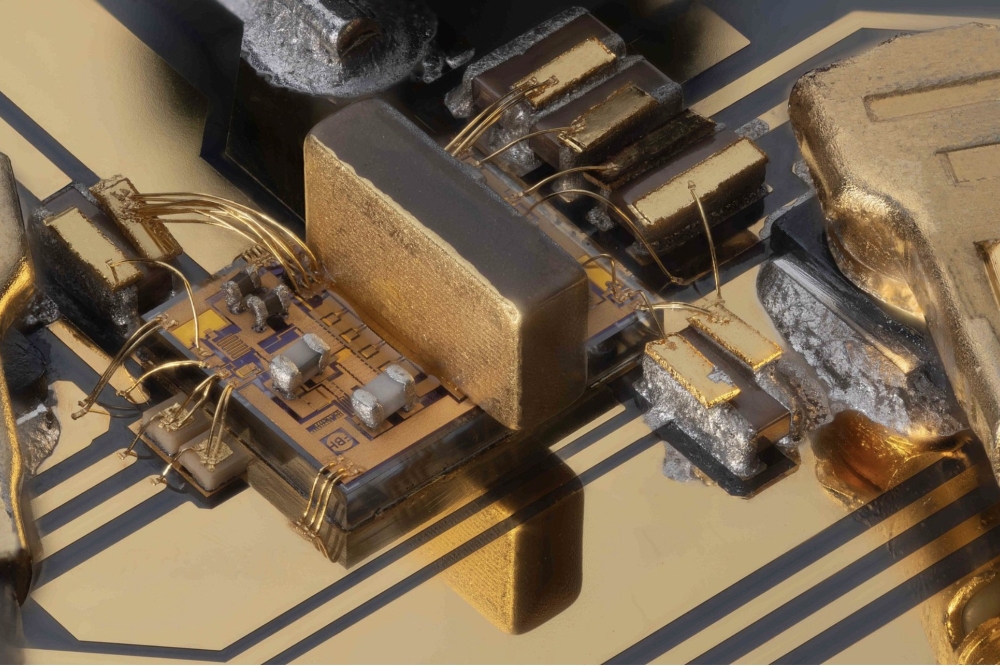

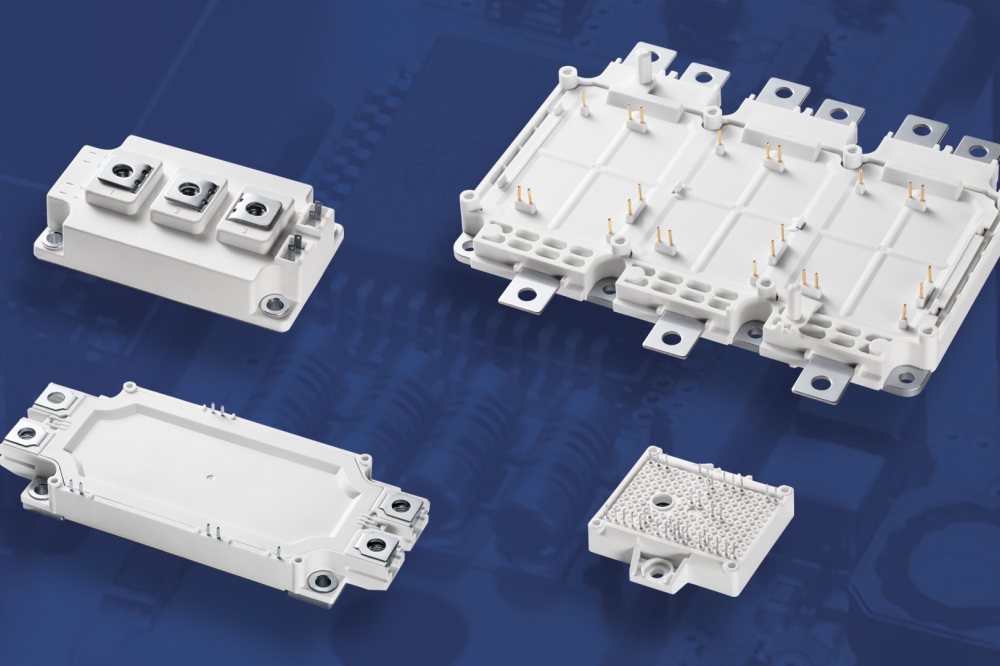

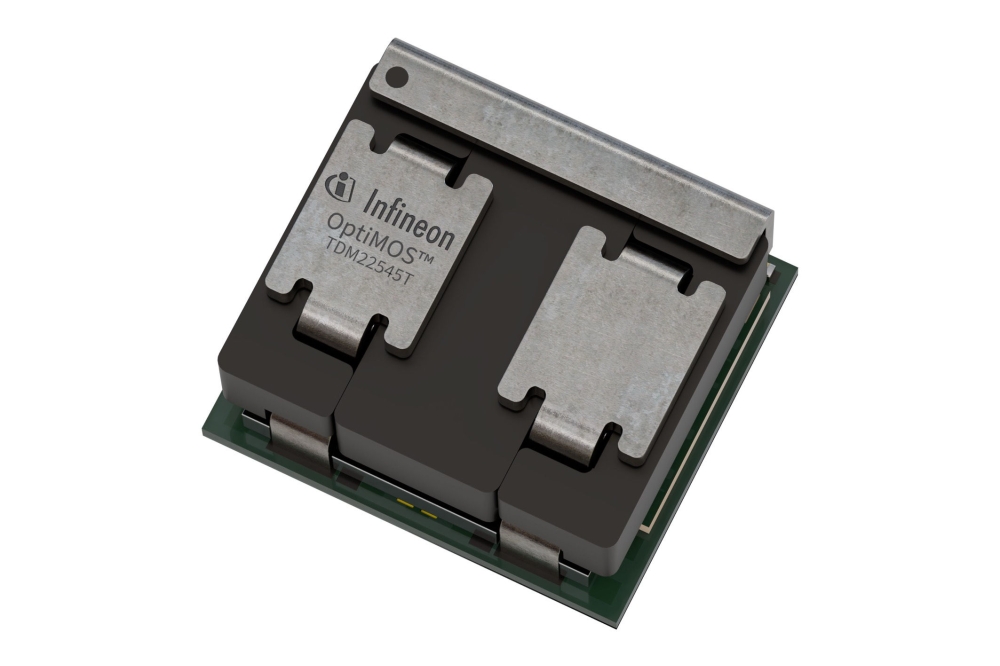

Amongst these trailblazers, Cambridge GaN Devices (CGD) claims that it is standing out from the crowd with its proprietary integrated circuit enhancement GaN technology, which it refers to as ICeGaN. The company is championing the combination of its ‘intelligent’ GaN HEMTs, which feature an enhancement-mode p-GaN HEMT rated at 650 V, and an IGBT. It’s a patent-pending pairing with the moniker Combo ICeGaN.

IceGaN is a form of smart power HEMT that features advanced sensing and protection capabilities.

According to Daniel Murphy, Director of Technical Marketing at CGD, the company’s ICeGaN is its core technology, as well as its unique selling point. “This is what we're building the company around. The DNA of CGD, if you like.”

One of the primary strengths of ICeGaN is that it provides ease of use. “You can essentially treat a GaN transistor like a MOSFET,” says Murphy. Due to this, it’s possible to use a very simple, low-cost driver to accompany the GaN HEMT.

Another great attribute of ICeGaN is that it facilitates zero-voltage switching, thanks to the inclusion of a Miller clamp. “There's no need for a negative voltage to be applied to switch the device,” says Murphy, explaining that this refinement allows the driver to be simpler and cheaper. What’s more, the Miller clamp ensures a very efficient turn-off of the GaN HEMT.

In addition to these valuable assets, absent in conventional GaN HEMTs, CGD’s ICeGaN technology has a slightly higher threshold voltage for the transistor.

“We've shifted it up to about three volts,” says Murphy, explaining that this adjustment brings ICeGaN technology in line with standard silicon devices. “Hence you can use standard silicon drivers.”

The slight increase in threshold voltage also eliminates the danger of spurious turn-on.

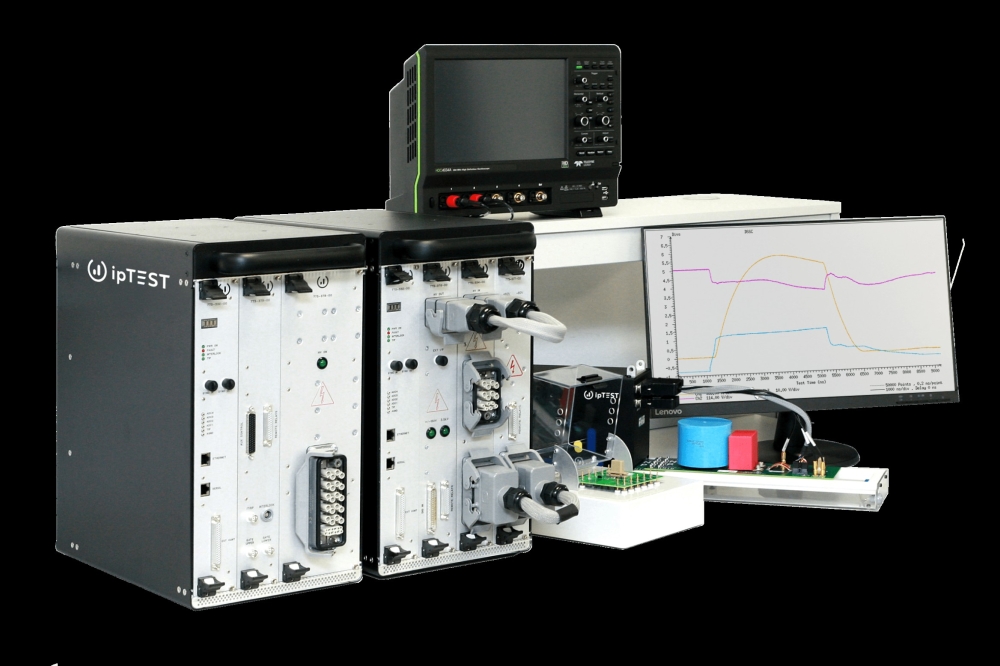

With Combo IceGaN, higher efficiencies are realised by drawing on the complementary benefits of both classes of transistor.

The power loss and efficiency of the IceGaN Combo is superior to that of the IGBT.

“GaN comes into play at light loads, where you have very low switching losses. It brings increased efficiency,” enthuses Murphy, who adds: “At high loads, and in some fault conditions, the robustness of the IGBT comes into play.”

While the levels of efficiency provided by Combo IceGaN are not quite as high as they are with a full SiC solution, it provides a cost saving of around 40 percent to 50 percent, according to Murphy. And compared with only IGBTs, efficiency is 3 percent higher, based on measurements that consider the Worldwide Harmonized Light Vehicles Test Procedure cycle. “That obviously translates into either a less expensive battery or extended range,” remarks Murphy.

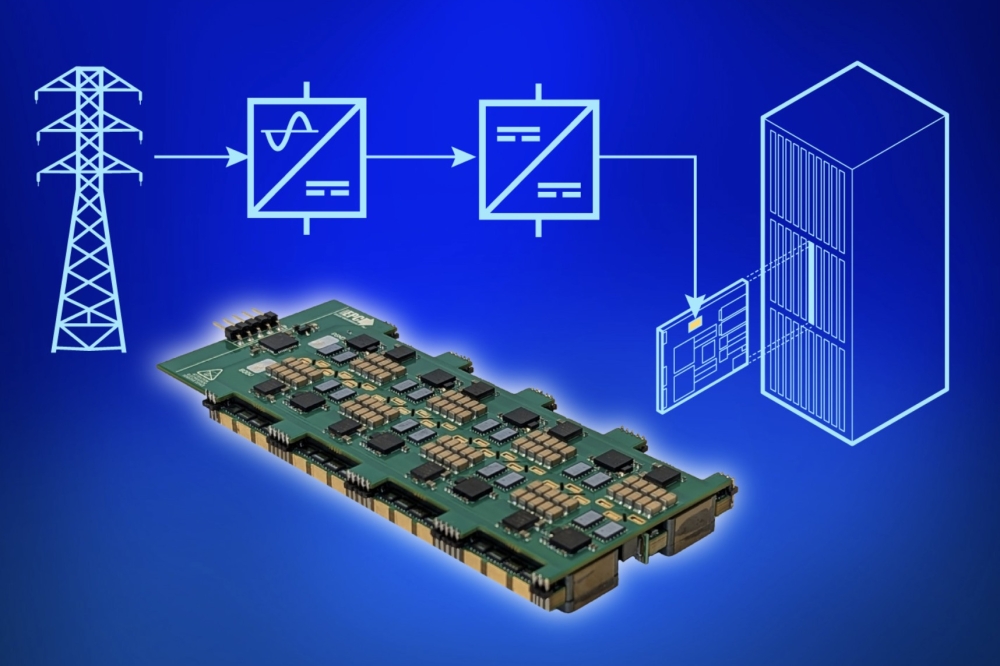

As well as targeting the power train, CGD is pursuing opportunities in on-board chargers and DC-to-DC converters in electric vehicles, as well as industrial data centres, through the development of more innovative approaches. In this sector, power densities and power levels tend to increase year-on-year. “So, we're needing to improve the form factor all the time, and investigate different ways to address the packaging to meet the thermal requirements,” says Murphy.

As all these applications involve very high power levels, the increase in chip area associated with additional features of ICeGaN, such as advanced sensing and the protection function, is relatively modest. Thanks to this, CGD is able to produce highly functional, competitively priced products.

Like many players in GaN power electronics, CGD is fabless, with chips produced at TSMC. This world-renowned Taiwanese foundry is responsible for the growth of epiwafers and their processing into devices. Packaging is undertaken at another partner, ASE.

As the Combo GaN technology can incorporate a range of IGBTs, CGD is planning to operate at the chip level within the supply chain. “We're looking for module partners, we're looking for car makers, tier ones that are interested to adopt this approach, and then we would support them with the sale of bare die,” says Murphy.

One of the reasons why CGD is focusing on the traction inverter within the electric vehicle market is the volume of GaN that’s required. “It is so much higher, because the power level is so much higher,” claims Muphy, who adds that the other big draw is the substantial technical challenge. “We're a company with lots of smart people, and we're very ambitious. So that's why we're targeting traction.”

Given the conservative nature of the automotive industry, it will take time for CGD to penetrate this market. The plan is to begin by launching discrete products for on-board chargers and DC-to-DC converters in 2026.

“The idea is for traction to try and enter a carmaker platform around 2028 timescale, and sooner than that with on-board chargers and DC-to-DCs,” says Murphy.

So, while the makers of SiC MOSFETs are going to face a stiff challenge from other wide bandgap devices, the competition is not going to begin immediately.